Mechanical Fabrication

Company

Media

Brochure

News

FASTOSI S.R.L. Synergy and Quality for Tailored Solutions

The active and continuous cooperation between the production and technical department, the suppliers and the company owners guarantees fast solutions to any technical issues. This is true both when supplying structural and mechanical parts, and when building the whole lines and testing it using our own personnel. We can fix wiring on the machine and connect the control cabinet to external collaborators if the clients request it.

Fastosi s.r.l. has always found, in its 30-years of experience, the elements and the strength to successfully propel itself into the future. Our first priorities are the excellent quality of our products and reliable customer support service, both before and after the sale.

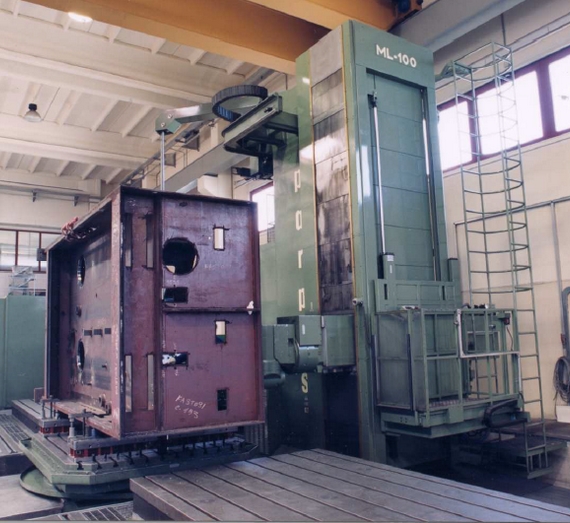

Processing machines

Boring milling machine a t Fastosi CNC

- Axis travels: 3500 x 1200 + 1500 x 2500 vertical

- 1800 x 1600 continuous rotary table, 14 tons

- Bi-rotary indexing head

- 40-position tool magazine

Boring milling machine Tiger RT 2500 CNC

- Axis travel: 2500 x 1200 + 500 x 1400 vertical

- 1200 x 1000 continuous rotary table, 5 tons

- Twin-spindle headstock

Vertical milling center OKK PCV 55 CNC

- Axis travel: 1000 x 660 x 650 vertical

Table 1200 x 660 1 ton - 4th continuous rotary axis, diameter 300

Milling and planing machine Pensotti visualizzata

- Axis races: 6000 x 1750 x 1200

- No. 3 milling heads on Corsa 500 ram

WORK CENTERA PORTALE FEELER FDM 8232

- FANUC numerical control

- Travels X 8200 Y 3700 Z 1000 mm

- Distance between columns 3200 mm

- Table dimensions 8000 x 3000 mm

- Tool changer 32 positions vertical/horizontal

HYDRAULIC PRESS BRAKE HILASAN

- Working force: 1750 kN

- Clearance between uprights: 2600 mm

- Maximum clearance between table and upper blade holder: 485 mm

Rammer stroke: 265 mm

LATHE DOOSAN PUMA 4100LMB

- Maximum rotating diameter: 790 mm

- Maximum turning diameter: 550 mm

- Maximum turning length: 2064 mm

- Maximum turning diameter from bar: 102 mm

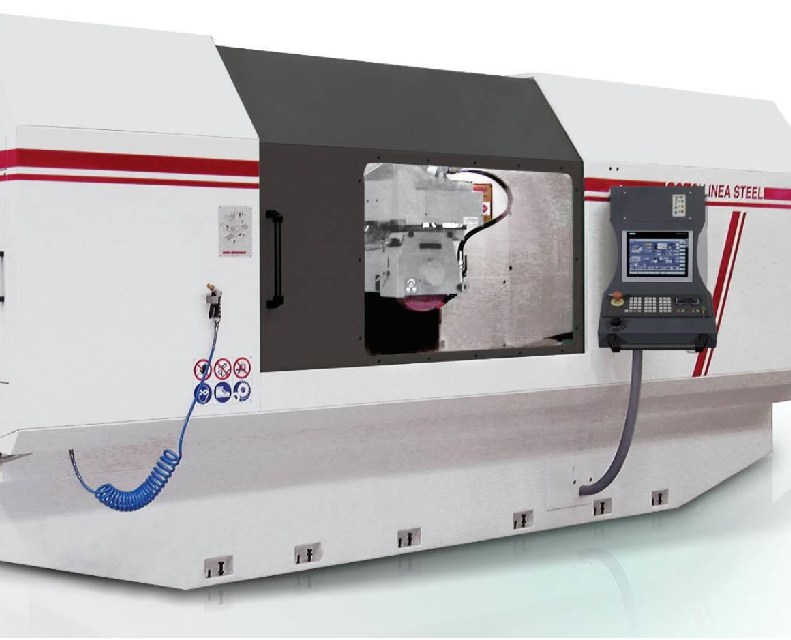

RECTIFICATION ROSA ERMANNO LINEA STEEL 13.7 CN

- Grinding length: 1500 mm

- Grinding width: 750 mm

- Grinding height: 600/800 mm

- Total stroke: 1350 x 1650 x 2250 mm

- Workpiece table surface: 1400 x 500 mm

- Permissible load: 1700 kg

- Transverse travel: 650 mm

AUTOMATIC ELECTROHYDRAULIC BAND SAW MEP SHARK NC 5.0

- Maximum rotating diameter: 790 mm

- Maximum turning diameter: 550 mm

- Maximum turning length: 2064 mm

- Maximum turning diameter from bar: 102 mm

AERIAL WORK PLATFORM Mod HAULOTTE SIGMA 16 PRO

- Maximum working height 15 m

- 7 m ARTICULATED boom

- Basket dimensions 1.20 x 0.80 m

- Load capacity 2300 kg

- Double ground and basket controls

How can we help you?

Specializing in large-scale mechanical carpentry

Fastosi S.R.L. specializes in the production of large mechanical structures and components, thanks to a production department equipped with cutting-edge machinery and highly qualified personnel. Our experience allows us to efficiently handle every stage of the production process, from machining to finishing, ensuring precise tolerances and consistent quality on complex and bulky components.

Integrated management technical office and production

One of the company’s strengths is the synergy between the Technical Office and the production departments, which allows us to quickly transform projects into reality. Each component is studied down to the smallest detail to optimize materials, processes, and production times. Our ability to adapt to specific customer needs allows us to offer customized solutions, even for highly technically complex orders.

Full support up to testing

Fastosi doesn’t stop at manufacturing: we offer a comprehensive service that includes assembly, on-board wiring, and electrical connections, including through collaboration with qualified external technicians. All systems are carefully tested before delivery, ensuring functionality and reliability. This integrated approach provides our clients with a single, expert partner, capable of overseeing every phase of the project through to final implementation.